Manufacturing

Making Cells in Michigan at Our ONE Circle Gigafactory

An Important Milestone on the Path to a North American Supply Chain

In October 2023, the first LFP cells rolled off ONE’s 10 MWh customer validation line at ONE Circle in Van Buren Township, Michigan. In April of 2023, we started producing Aries LFP modules at Piston Automotive, also in Michigan.

ONE will also manufacture both our Aries Grid ESS and Aries Grid Module products in the U.S., delivering a vertically integrated energy storage solution—from cell to system—fully designed and built in the U.S.

ONE will also manufacture both our Aries Grid ESS and Aries Grid Module products in the U.S., delivering a vertically integrated energy storage solution—from cell to system—fully designed and built in the U.S.

ONE Circle Produces First LFP Cell

ONE Circle

ONE Circle has 20 GWh capacity for battery cell manufacturing. The site will provide thousands of manufacturing jobs. We anticipate cells produced at ONE Circle will be fully IRA compliant for both ONE and our customers.

Scaling Up in Phases

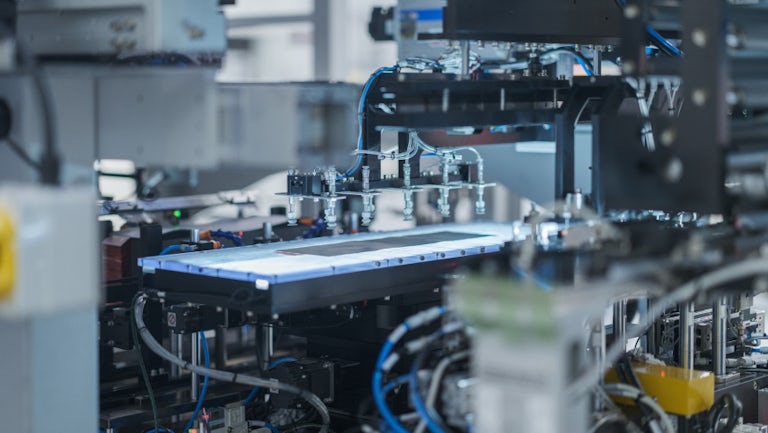

This initial production line manufactures cells using the same process ONE plans to use at a larger scale within the 660,000 sq. foot factory.

The smaller scale 10 MWh line allows ONE to validate its production intent cell designs, while sharing samples with customers for testing purposes.

Once validated, the process of scaling up manufacturing of LFP cells at a larger multi-GWh scale will begin next year.

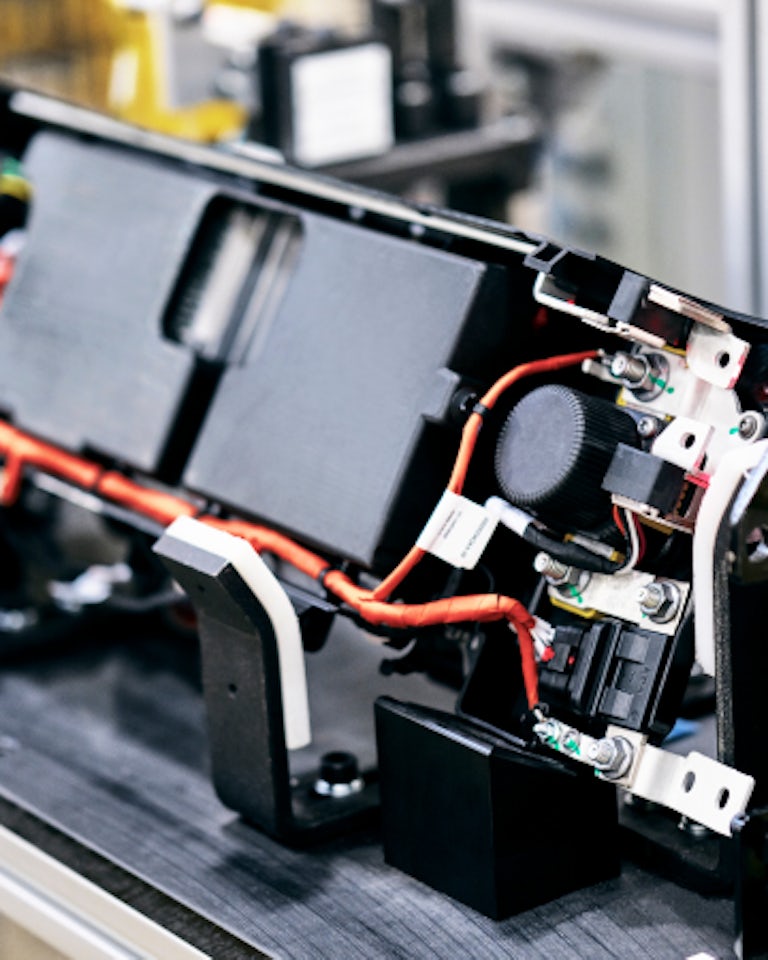

Aries LFP Pack Manufacturing

Aries LFP is produced on a dedicated battery pack assembly line in Michigan. The Aries LFP packs ONE produces are utilized in commercial vehicle applications.

Aries LFP Pack Assembly

ONE Circle

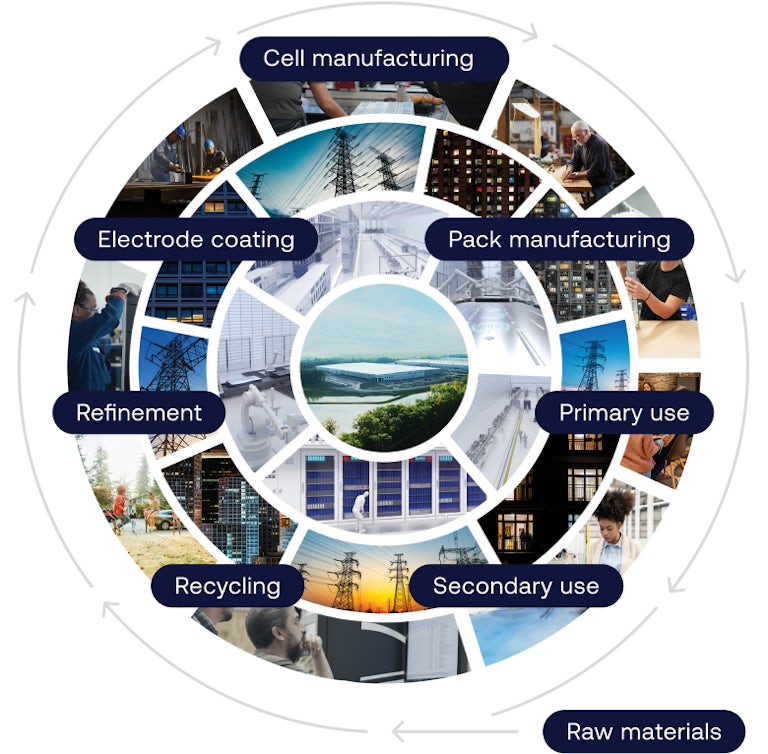

A New Model for Battery Factories

Material Processing

ONE will process battery materials in-house and have more control over our supply chain, prioritizing North American materials and chemistries that minimize environmental impact.Cell Manufacturing

At a time when demand is expected to increase exponentially, we will be one of the few wholly U.S.-owned manufacturers of LFP and anode-free cells.Cost-Effective Energy Storage

By integrating cell manufacturing with energy storage and optimization, we will provide utilities with cost-effective, flexible and high-capacity energy storage. We will also provide renewable energy to power ONE Circle and the surrounding community.Pack Manufacturing

Working with key partners on commercial and consumer applications, we will manufacture battery packs that provide industry-leading range and volumetric energy density.Recycling and Second Life

ONE will use recycled materials in our products and design them to have a productive second life.Powering Michigan

ONE Circle will create over thousands of new green jobs in Michigan. It will increase local renewable energy access, build the future of electrification in the state and solidify Michigan’s place as the leader in automotive technology and manufacturing.

Sustainability

We aspire to reduce the carbon footprint of the products we manufacture. To that end, we will pursue circular strategies. One of these is our aim to integrate a closed loop recycling feed into our production process.

7 reasons why iron is what's next in electric.

Learn why LFP chemistry is the future of energy storage.

Subscribe to our newsletter

Let's talk about finding the right energy storage solution for you.