Sustainability

A sustainable transition requires abundance.

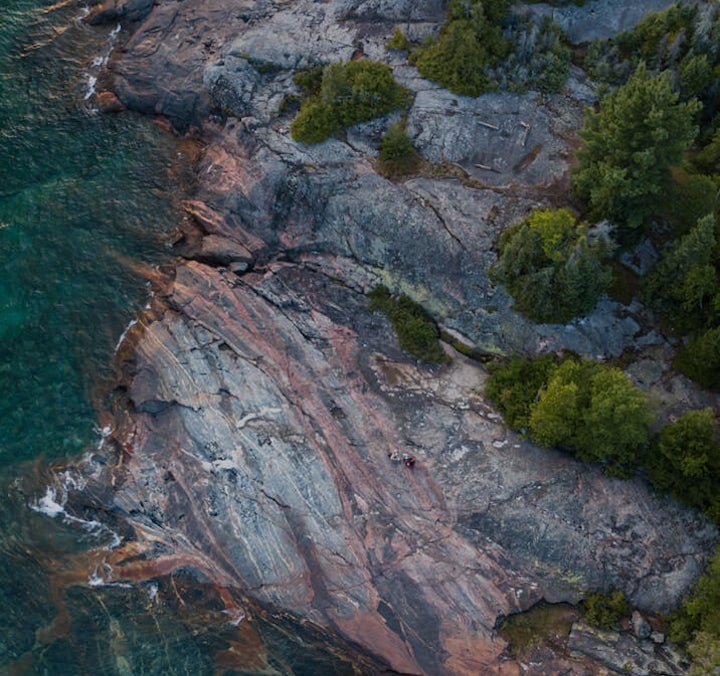

Pictured: manganese ore.

The trouble with global supply chains.

Some of the raw materials the auto industry depends on for energy storage are in short supply, subject to sudden price increases and sourced from far-off countries. Vulnerable to disruption, global supply chains are unsustainable almost by definition. To be sustainable, a supply chain must be secure, reliable and abundant.

Nickel and cobalt are not the future.

The U.S. is short on nickel. Nickel prices are historically volatile, at times doubling within a single month before dropping. 70% of cobalt is sourced from places with labor, health and safety problems, and the cobalt supply is projected to fail to meet demand by 2030.

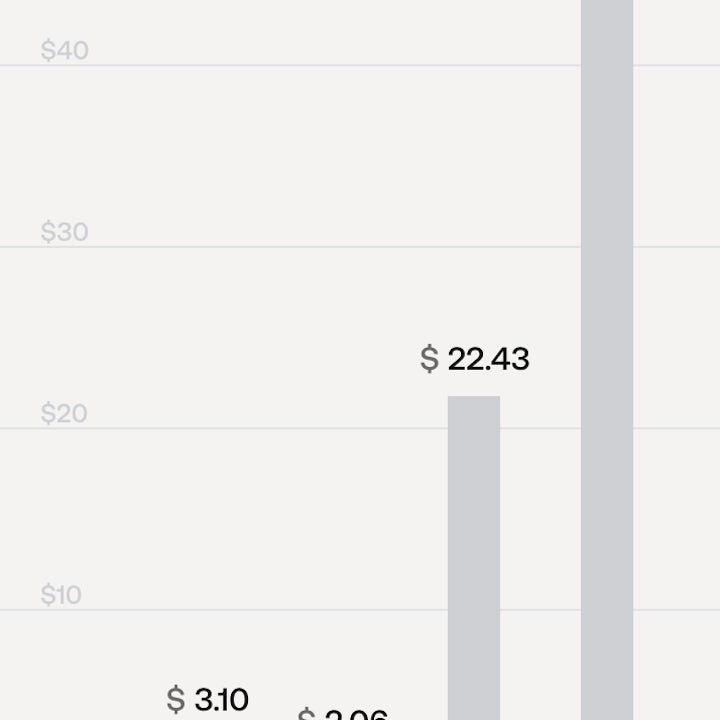

Abundant, low-cost materials.

Today’s battery chemistries must be built on a foundation of abundant materials that are lower in cost. Compare the cost of iron and manganese to the cost of nickel and cobalt. By using abundant, cost-efficient raw materials like iron and manganese instead of nickel and cobalt, we can lower the cost of electric vehicles and promote mass adoption. The battery in an electric vehicle represents 35 to 40% of the total vehicle cost.

Iron and manganese

are abundant.

Manganese is the fifth most abundant metal in the Earth’s crust. 85% of U.S. iron production comes from local deposits around Lake Superior in Minnesota and Michigan — home of our new ONE Circle Gigafactory. ONE has future-proofed its supply chain against disruption by basing the LFP chemistry in Aries™ LFP and Aries™ II on easily-obtained, locally-sourced and affordable iron. The dual-chemistry in Gemini™ relies on both iron and plentiful manganese.

More sustainable chemistries.

At ONE, we knew that creating the necessary conditions for mass EV adoption would require reevaluating materials long overlooked by the industry. The ONE team believed lithium iron phosphate (LFP) held the key to bringing a sustainable (and much safer) chemistry to market. The LFP we use in our Aries products (and in Gemini for everyday driving) not only matches nickel-and-cobalt-based chemistry for power and range — it mitigates against battery fires. The advanced anode-free chemistry in Gemini (delivering 450 miles of extended range) is based on easily sourced manganese.

System-level sustainability.

ONE is creating value through engineering and system design — not just chemistry. The decision to focus our new chemistries on abundant, sustainable raw materials like iron and manganese demanded the invention of new system solutions. For example, our Structural Cell-to-Pack™ architecture enables 76% system-level energy density in a compact format.

Innovative energy systems.

Gemini’s dual-chemistry architecture deploys LFP for daily driving and a second, manganese-based, anode-free chemistry for longer trips. In the anode-free cell, we replaced graphite with a bare copper foil, which let us pack in more active material, creating a high energy cell (1,007 Watt hours per liter). The two batteries work in tandem with a battery management system capable of machine learning and a DC-DC converter that moves energy from cell to cell seamlessly in both directions.

ONE Circle Gigafactory

ONE Circle is capable of manufacturing enough cells to produce 240,000 Aries II and Gemini packs annually.

Subscribe to our newsletter

Let's talk about finding the right energy storage solution for you.