Safety

Safer chemistry saves lives.

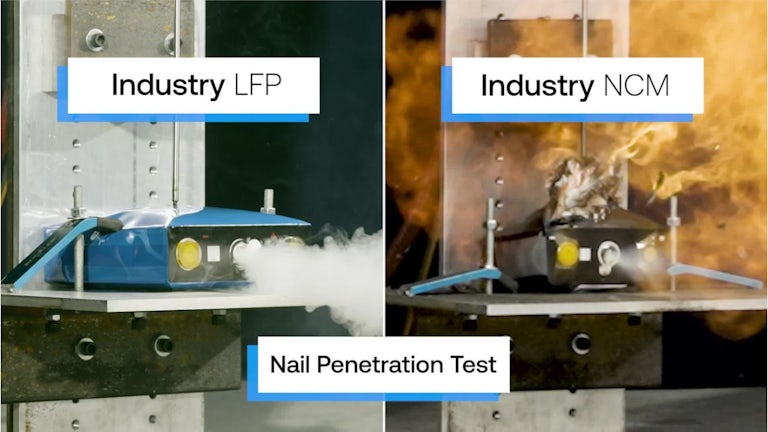

Thermal runaway and battery fires explained.

All metal oxide batteries contain oxygen among their ingredients.

If you have these three things, you get thermal runaway:

A heat source or ignition.

Things that burn (like the combustible liquid inside a battery).

Sufficient oxygen released to sustain the fire.

That’s why most battery designs contain boxes upon boxes — to prevent a fire in one cell from spreading to the others in a chain reaction that can consume an entire vehicle.

Moving to LFP.

We asked, “What if the EV battery chemistry could be replaced with something safer?” We re-evaluated an overlooked solution: lithium iron phosphate (LFP). Made from abundant iron found all over the world (including Michigan), LFP is lower in cost than nickel-and-cobalt-based chemistry and lasts twice as long. And LFP has its oxygen bound up so tightly with its phosphate that it holds on to its own oxygen with an iron grip — which makes it a lot safer.

Packing in more cells.

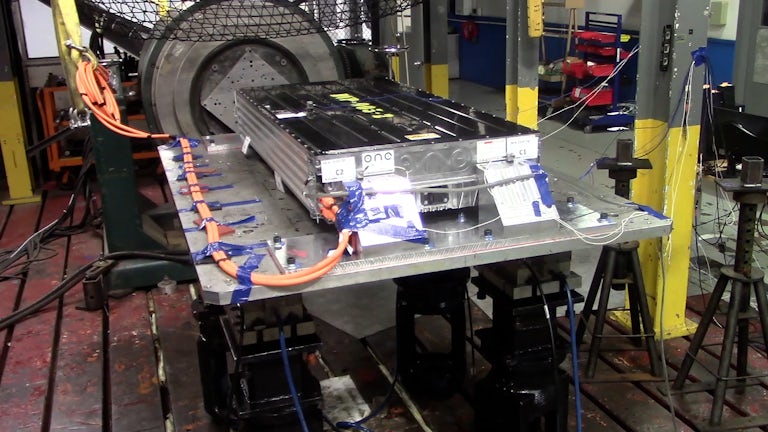

Thanks to LFP, all that battery space formerly taken up by fire mitigation boxes could now be used for energy — matching or exceeding the power of nickel-cobalt-based batteries. Starting with Aries™ LFP, we improved safety with design instead of chemistry alone. At ONE, we don't want to simply chase the highest energy chemistry. We’re looking for the highest energy system.

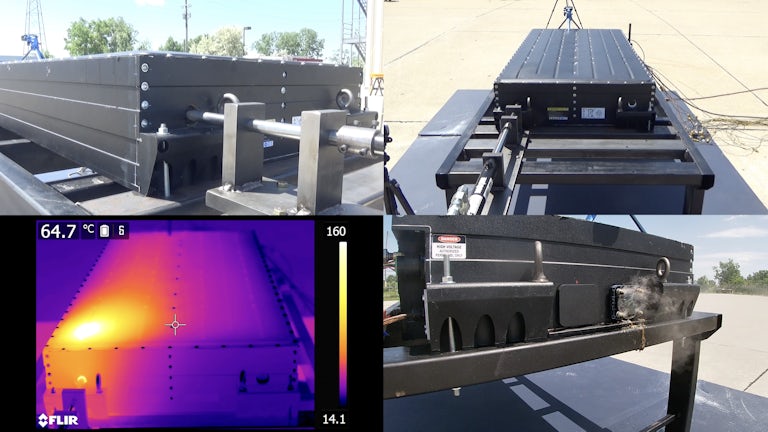

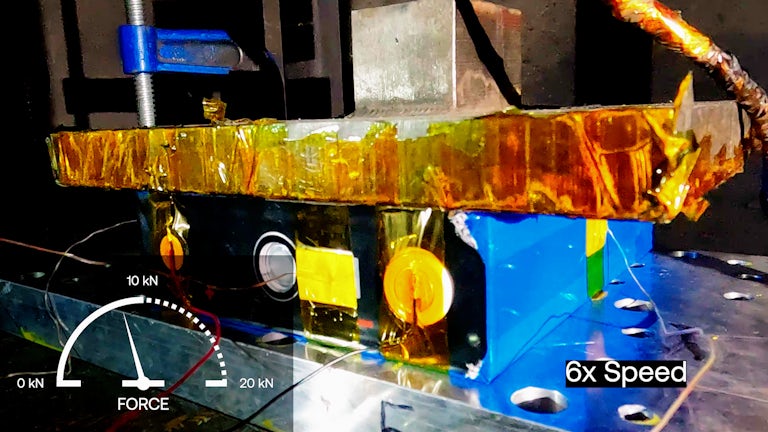

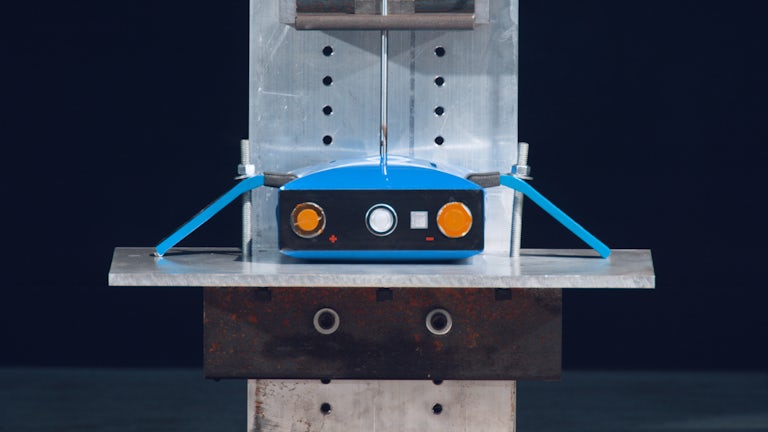

Safety testing process.

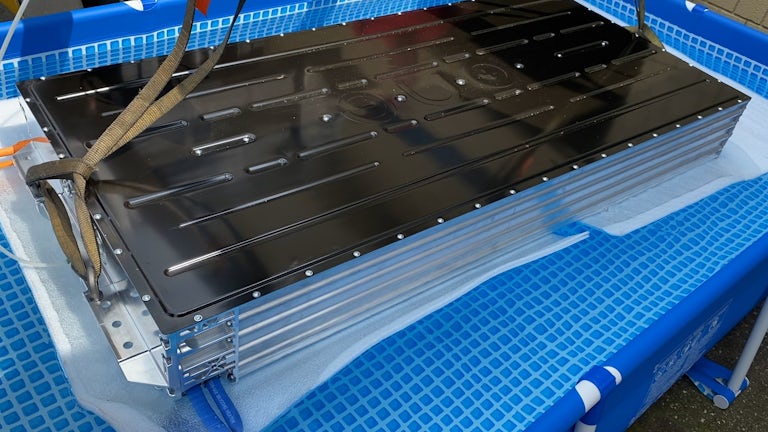

Prior to launch, our batteries are subjected to a rigorous validation process.

Overcoming the obstacles to electrification.

We’re meeting the challenges of range, safety and sustainability.

Subscribe to our newsletter

Let's talk about finding the right energy storage solution for you.