Energy Density

Doing more with the same footprint means lower system cost and LFP safety without compromise.

More density means lower cost.

In grid-scale energy storage, cost is driven by how much energy fits into a fixed footprint. Higher system energy density reduces balance-of-system costs—containers, steel, foundations, installation, and site work—driving down installed $/kWh. By delivering more MWh per ESS, ONE lowers total project cost without changing chemistry or increasing risk.

More density means better performance.

In defense, rail, and industrial applications, higher energy density enables lighter, more compact systems while preserving LFP's inherent advantages: safety, long cycle life, and freedom from nickel and cobalt. ONE’s system-level approach closes the performance gap traditionally associated with LFP. All without sacrificing reliability or supply chain resilience.

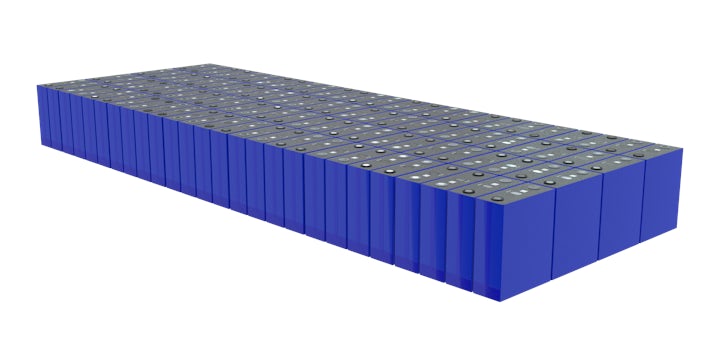

Pack-level energy density.

Because our chemistries are safer, we can pack our cells more tightly than nickel-and-cobalt-based batteries. That’s because nickel-and-cobalt-based batteries need to devote a significant percentage of battery space to fire mitigation.

Site-level energy density.

In the world of stationary storage, site-level energy density is a top consideration.

By combining the flexibility we have in design as a vertically integrated manufacturer with our systems-thinking approach, ONE has also achieved a new benchmark in site-level ESS energy density with a 7+ MWh DC ESS that can be arranged back-to-back on three of four sides. All without sacrificing serviceability.

Subscribe to our newsletter

Let's talk about finding the right energy storage solution for you.