Newsroom

6K and ONE Announce Collaboration to Create Low-Cost Gemini Material

March 9, 2022 | Press Release, Gemini

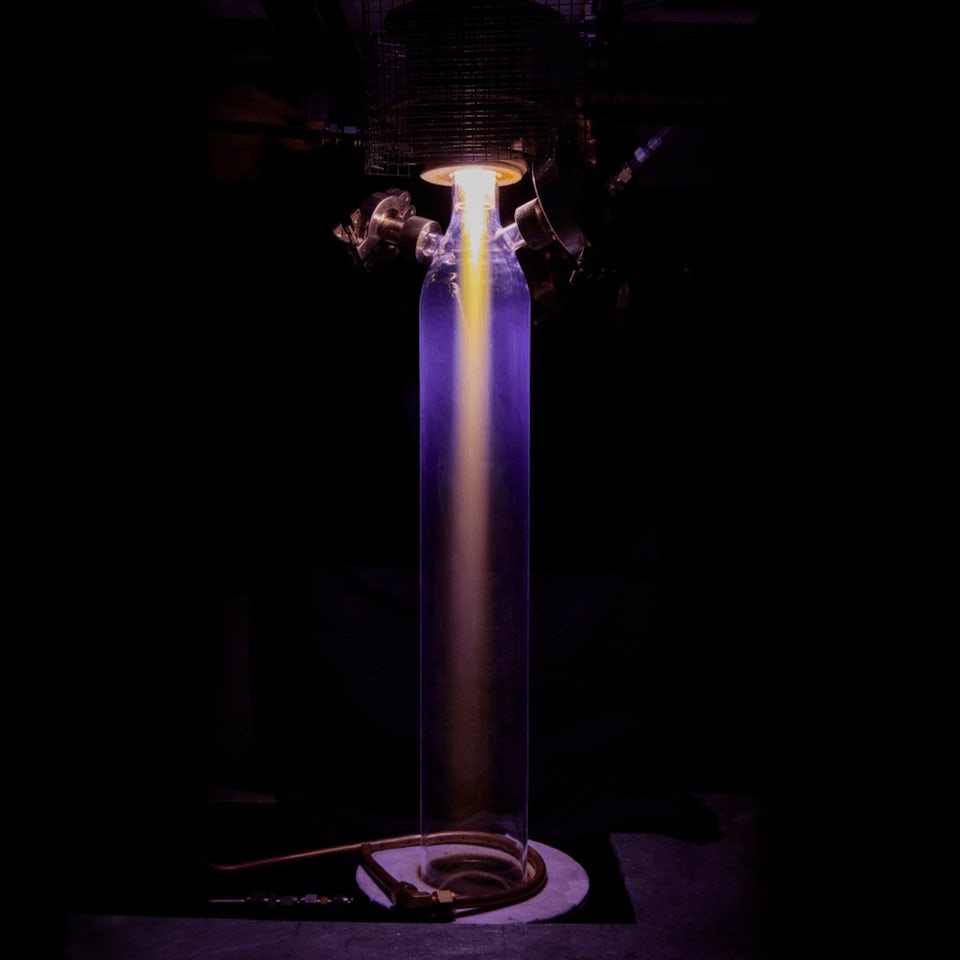

The new material, produced on 6K’s UniMelt® microwave plasma production system, will be used in ONE’s range-extended Gemini battery system.

North Andover, MA and Novi, MI, March 9, 2022 – 6K, a leader in the production of sustainable advanced materials for lithium-ion batteries, and Our Next Energy Inc. (ONE), a Michigan-based developer of innovative energy storage technology, today announced a partnership as ONE looks to scale up and commercialize its Gemini cell chemistry. The organization signed a letter of intent outlining how the companies will work together to significantly lower the cost and manufacturing capital required when producing this new battery material.

Mujeeb Ijaz, founder and chief executive officer of ONE said, “ONE is focused on developing the most cost-effective and novel methods for producing its Gemini cathode material using 6K materials and processes. Our focus is on building battery technology from a more sustainable, localized supply chain, thereby sharply reducing battery materials cost. Comparing conventional cathode material processing to 6K’s novel approach gives me confidence that we can have a low-cost cathode material for Gemini.”

ONE recently demonstrated a proof-of-concept battery that powered an electric vehicle 752 miles without recharging. The results were validated by a third party using a vehicle dynamometer where the test vehicle, a Tesla Model S retrofitted with an experimental battery, achieved 882 miles at 55 mph.

“This agreement is significant on many fronts. For us at 6K, ONE’s use of our proprietary cathode material emphasizes our vision and mission of manufacturing battery materials at lower cost in the United States, helping to significantly drive down the overall costs of EVs with sustainably produced materials,” said Sam Trinch, group president for 6K Energy.

Last spring, 6K announced a $30M investment in the Battery Center of Excellence for its 6K Energy division. The new 33,000 sq/ft state-of-the-art pilot production facility will accommodate multiple pilot scale UniMelt systems with a total annual capacity of 400-500 MWh. This facility will be the largest plant in the United States capable of producing NMC811 cathode material. This will support full scale development of materials such as high energy density, single crystal cathode; low-cost, conflict free cathode; solid-state electrolyte materials; and materials for the anode. The expansion will create pilot production capabilities to fully support partner qualification, providing a gateway direct to domestic production.

Subscribe to our newsletter

Let's talk about finding the right energy storage solution for you.